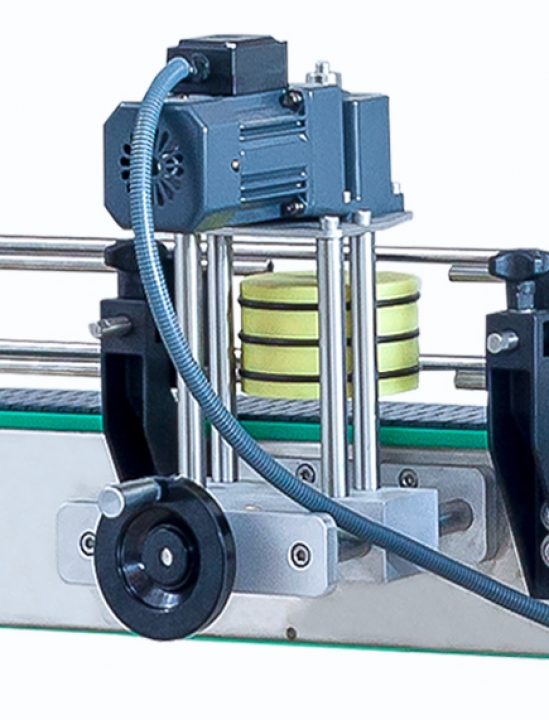

Bottle adjustment system (separator)

Page Detail

Bottle adjustment system (separator)

Bottle adjustment system (separator)

Model : SVM-S003

Technical specifications:

- construction of the system made from Stainless Steel AISI304, other parts made from aluminum

- 1 Reducer motors. (180 Watt)

- The system will be synchronized with sleeve machine

- Frequency driver is used to control the speed

- Can be easily adjusted manually to fit the products

-

Bottle adjustment system: This system refers to a mechanism used in a production line to ensure proper alignment and positioning of bottles of different sizes. It allows for adjustments and alignment of bottles based on their dimensions.

-

Bottle sorting system: This system is designed to manage the complex flow of bottles in a production line. It arranges, aligns, and maintains bottles in the correct position, ensuring the seamless progression of the production process.

-

Bottle separation system: This system is utilized to separate bottles of different types or sizes from each other in a production line. It enables the segregation and proper routing of bottles based on their specific characteristics for different processing operations.

-

Bottle separation technology: This technology involves automated or mechanical methods to identify and separate bottles with different characteristics. Components such as optical sensors, conveyor belts, and robotic systems can be employed to achieve bottle separation based on specific criteria.

-

Automatic bottle sorting system: This system is a mechanized mechanism that operates without human intervention. Through the use of sensors and control systems, it automatically sorts, arranges, and positions bottles. It is often preferred to enhance the efficiency of the production process.

-

Bottle sorting and separation mechanism: This mechanism is responsible for arranging, grouping, and separating bottles in a production line. It separates bottles based on criteria such as size, shape, color, or other attributes, and directs them to the appropriate processes.

-

Bottle processing and separation equipment: This equipment facilitates the rapid and efficient processing and separation of bottles. Conveyor systems, robotic arms, vacuum suction systems, and other automation technologies can be utilized to optimize the processing workflow.

-

Bottle classification and separation system: This system classifies and separates bottles based on specific criteria such as volume, material, shape, or cap type. It groups bottles accordingly and directs them to relevant processing operations.

Share

Product Information

| Size: | |

|---|---|

| Colors | |

| Material |

Sleevemak Machinery Industry